PDF(4593 KB)

PDF(4593 KB)

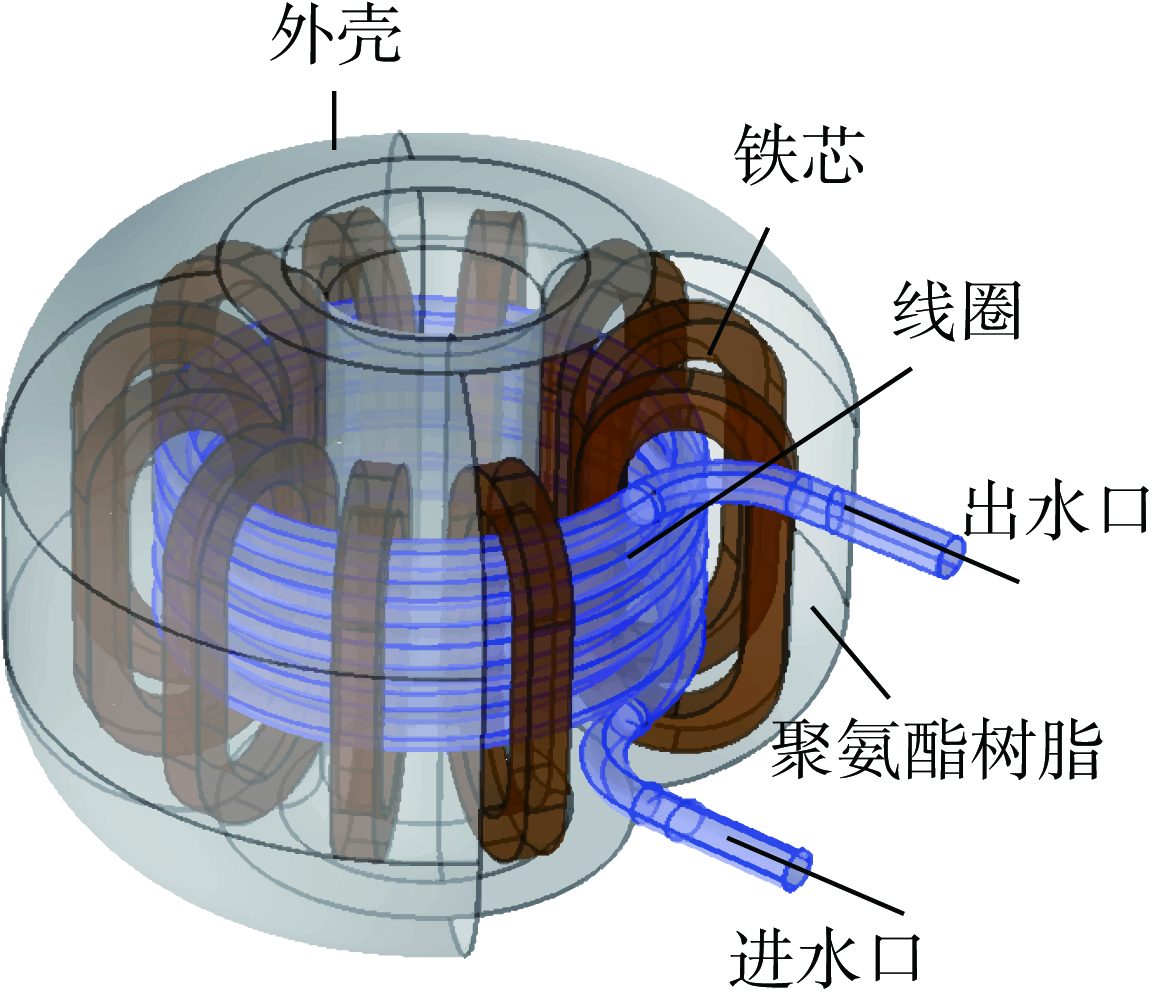

新一代±800 kV/8 GW特高压直流换流阀用饱和电抗器温升试验及比对分析

刘帮虎, 王加龙, 潘励哲, 杨勇, 石岩, 李明

电力建设 ›› 2020, Vol. 41 ›› Issue (10) : 90-97.

PDF(4593 KB)

PDF(4593 KB)

PDF(4593 KB)

PDF(4593 KB)

新一代±800 kV/8 GW特高压直流换流阀用饱和电抗器温升试验及比对分析

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Temperature Rise Test and Comparative Analysis of Saturable Reactors for New Generation of ±800 kV/8 GW UHVDC Converter Valve

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |